Description

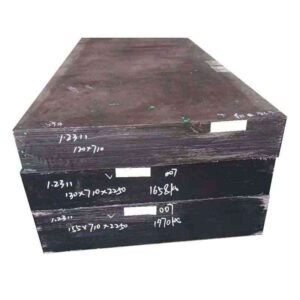

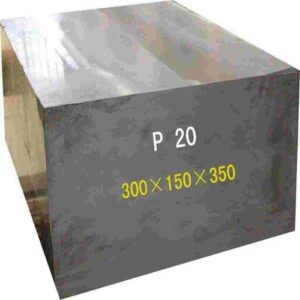

⇒Commonly used materials

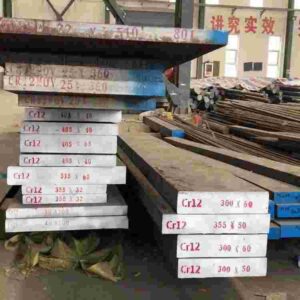

45# Q235A 40CR P20

⇒Uses and performance

High hardness, high wear resistance, high heat resistance, high corrosion resistance

The main properties of die steel include high hardness, high wear resistance, high heat resistance and high corrosion resistance. These properties make die steels excellent in a variety of industrial applications.

The use and role of die steel

Automobile manufacturing: Die steel is widely used in automobile manufacturing, and its high hardness and high wear resistance can withstand high-strength impact and friction to ensure the service life and processing quality of the mold 1.

Electronics and home appliance manufacturing: In electronics and home appliance manufacturing, the high hardness and high precision of die steel can ensure the dimensional accuracy and surface quality of the product, while its high corrosion resistance ensures the stability and durability of the mold in a humid environment1.

Aerospace: The manufacturing process of aerospace products requires a large number of molds to complete the forming and processing of complex parts, and the high hardness and strength of mold steel can meet these requirements1.

Medical device manufacturing: In medical device manufacturing, the high hardness and high precision of mold steel can ensure the dimensional accuracy and surface quality of medical devices, and its high corrosion resistance ensures the stability and durability of medical devices in wet environments 1.

Classification of die steels and their properties

Cold work die steel: It is mainly used to manufacture molds for pressing and forming workpieces in a cold state, such as cold stamping dies, cold stamping dies, etc. This type of die steel has high wear resistance and impact toughness 2.

Hot work die steel: used for workpiece processing at high temperatures, such as hot forging dies, hot extrusion dies, etc. Commonly used hot work die steels include alloy die steels with medium to high carbon content, and sometimes high-alloy austenitic heat-resistant die steels2.

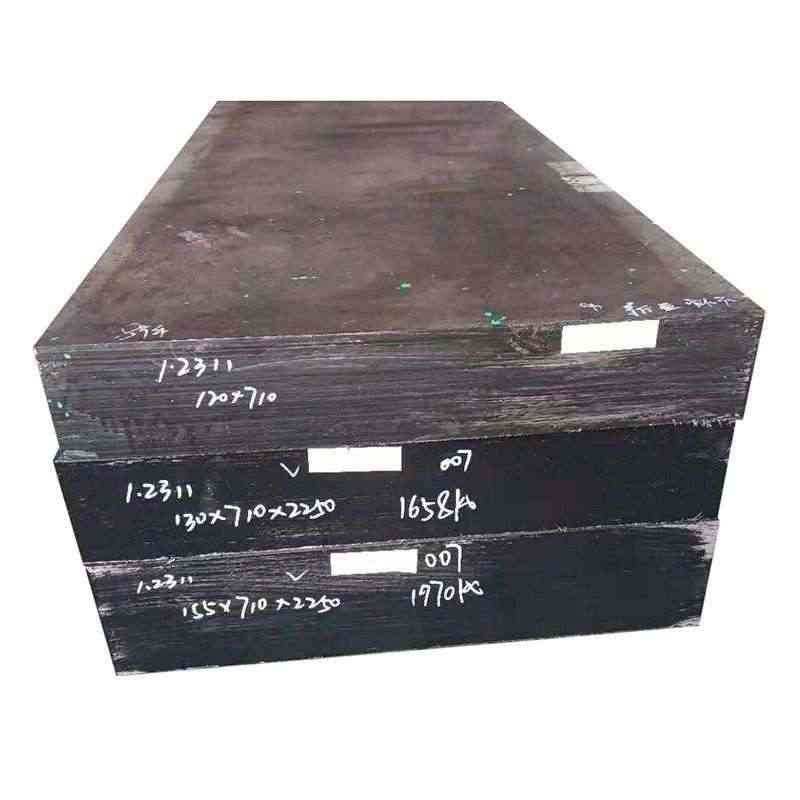

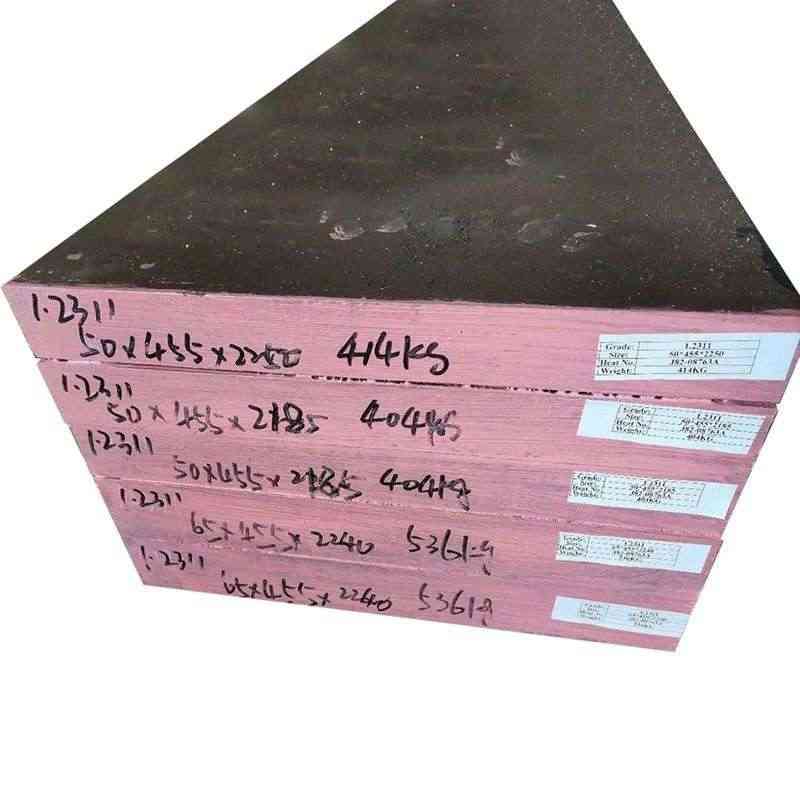

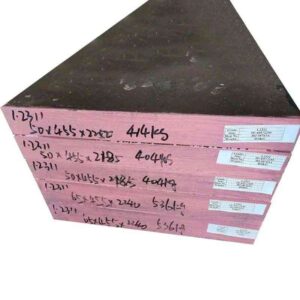

Mould steel for plastic molding: used to manufacture plastic moulds, including carbon structural steel, carburizing plastic mould steel, pre-hardened plastic mould steel, etc. These steels have different performance characteristics to meet the special requirements of plastic products2.

Methods to improve the performance of die steel

Alloy composition adjustment: By adjusting the alloy composition in the steel, such as adding elements such as carbon, chromium, molybdenum, vanadium, etc., the hardness, wear resistance and corrosion resistance of the steel can be improved3.

Smelting process improvement: Processes such as electroslag remelting and vacuum arc remelting can significantly improve the purity and microstructure density of steel, thereby improving its performance 3.

Heat treatment: Through heat treatment processes such as annealing, normalizing, quenching, and tempering, the properties of steel can be further optimized to meet different usage needs3.

In summary, die steel plays an important role in various industrial fields due to its excellent properties and wide range of uses. Through alloy composition adjustment, smelting process improvement and heat treatment, its performance can be further improved to meet the needs of different application scenarios.